Call: 07971891491( PIN:440)

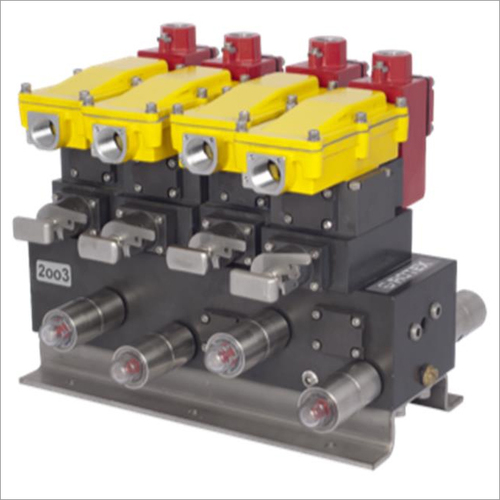

Redundant Valve 1oo2 - 1/8'' till 1/4''

Product Details:

- Connection Type 1oo2 Configuration

- Valve Size 1/8 to 1/4

- Features Redundant operation ensures high reliability

- Valve Type Pneumatic

- Material Carbon Steel and Aluminum alloy

- Control System Manual and Automated

- Sealing Precision sealing for leak-proof performance

- Click to View more

X

Redundant Valve 1oo2 - 1/8'' till 1/4'' Price And Quantity

- 10 , , Piece

Redundant Valve 1oo2 - 1/8'' till 1/4'' Product Specifications

- Carbon Steel and Aluminum alloy

- Precision sealing for leak-proof performance

- Manual and Automated

- Standardized connection pins for flexibility

- Balanced design optimized for redundancy

- Safety Instrumented Systems

- Low energy consumption design

- Compressed Air

- Black

- Standard

- Compact structural design

- 24V DC

- Redundant Valve -1oo2 - 1/8'' till 1/4''

- 1/8 to 1/4

- Rated for high-pressure operations PSI

- Redundant operation ensures high reliability

- 1/8 to 1/4

- Operates effectively in varied temperature ranges

- Redundant Valve System

- 1oo2 Configuration

- Pneumatic

Redundant Valve 1oo2 - 1/8'' till 1/4'' Trade Information

- 1000 , , Piece Per Month

- 7 Days

Product Description

The Redundant Valve 1oo2 (1/8" to 1/4") is a fail-safe component used to ensure continuous fluid or gas flow by providing backup redundancy. Key parts like the housing, sealing materials, and valve core are crafted from corrosion-resistant stainless steel or brass, ensuring durability. The valve utilizes advanced manufacturing techniques like CNC machining for precision and reliability. Commonly used in oil and gas, medical, and automotive industries, it prevents system failure and enhances safety. Available in various finishes, this valve ensures uninterrupted operation in critical applications, improving reliability and operational longevity across various sectors.

Send Inquiry

Send Inquiry