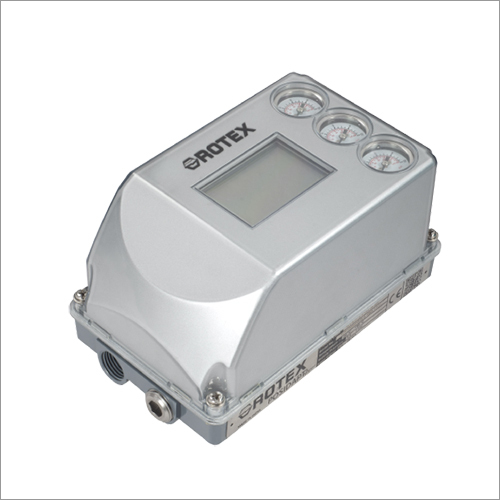

Regulating Actuator (Electro Pneumatic Positioner)

Product Details:

- Valve Size Varies (specifications available for specific sizes)

- Control System Electro Pneumatic Positioner

- Connection Type Flanged

- Valve Type Butterfly valve or other suitable valve types

- Material Aluminum actuator body stainless steel components

- Features Precise positioning durable design energy-efficient

- Sealing EPDM or PTFE sealing for leak-proof operation

- Click to View more

Regulating Actuator (Electro Pneumatic Positioner) Price And Quantity

- 10 Piece

Regulating Actuator (Electro Pneumatic Positioner) Product Specifications

- Standardized port sizing based on model

- Varies (specifications available for specific sizes)

- Black

- Precise positioning durable design energy-efficient

- Aluminum actuator body stainless steel components

- Pneumatic electrical control system

- Electro Pneumatic Positioner

- Standard

- Electro Pneumatic Positioner

- Up to 8 bar (can vary by model)

- Robust mounting pin for actuator system

- 24V DC or other control voltage

- High performance disc suitable for regulating

- EPDM or PTFE sealing for leak-proof operation

- Butterfly valve or other suitable valve types

- Regulating flow in industrial processes

- Air gases liquids

- Flanged

- -20°C to 80°C

- Piston-operated actuator with positioner

- Compact and modular actuator design

Regulating Actuator (Electro Pneumatic Positioner) Trade Information

- 1000 Piece Per Month

- 7 Days

Product Description

By transforming electrical signals into pneumatic pressure, a Regulating Actuator (Electro-Pneumatic Positioner) precisely regulates valve movement. It incorporates solenoids, pressure regulators, and feedback sensors for high-precision operation and is constructed from stainless steel (for resistance to corrosion) and aluminium alloys (for strength and lightweight durability). It improves automation in the power, water treatment, chemical, and oil and gas sectors. It is available in single-acting and double-acting varieties and is designed with CNC-machined components and microprocessor-based control. It is resistant to extreme circumstances and is finished with protective coatings. Its real-time changes ensure smooth industrial operations by improving system reliability, minimising energy waste, and optimising flow control.

Send Inquiry

Send Inquiry